Short By

Color

Series

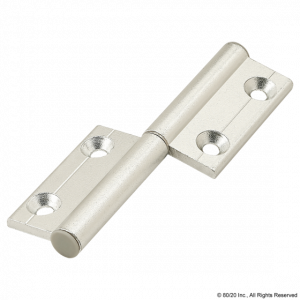

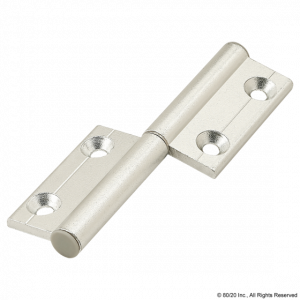

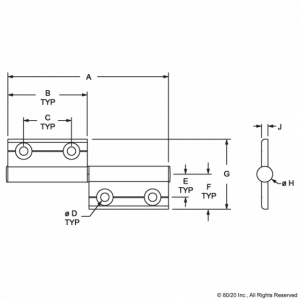

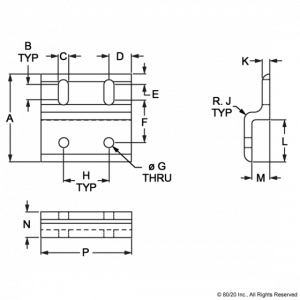

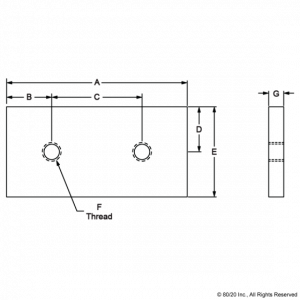

Part No: 2324-2

20 Series 4 Hole – Concealed Hinge

The 4 hole - concealed hinge allows you to design doors with hidden hinges when the door is closed. The hinge mounts to the inside of the frame, which makes enclosures more secure; they are not able to be dismantled when the door is shut.

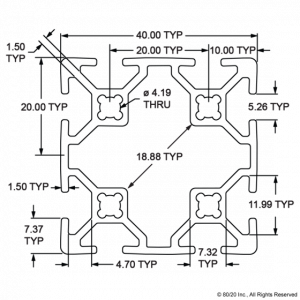

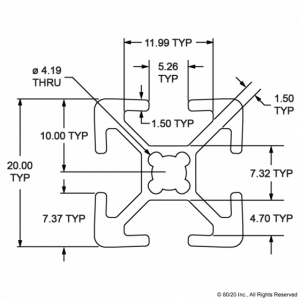

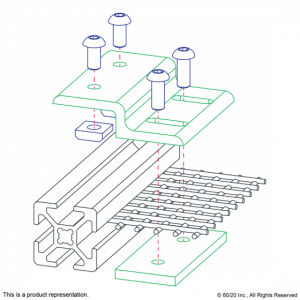

Part No: 20-4040

40mm X 40mm T-Slotted Profile – Eight Open T-Slots

20-4040 is a 40mm x 40mm metric 20 series square T-slot profile with eight open T-slots, two on each 40mm face. The profile is smooth, which makes it resistant to dirt and debris buildup while also being easy to clean. The 20-4040 profile is compatible with 20 series fasteners. The eight open T-slots and strength make it a great choice for automation applications, machine frames and workstations.

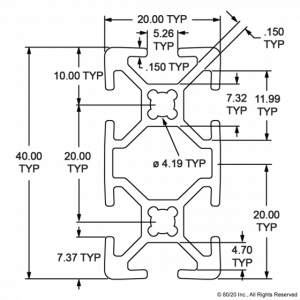

Part No: 20-2040

20mm X 40mm T-Slotted Profile – Six Open T-Slots

20-2040 is a 20mm x 40mm metric 20 series rectangular T-slot profile with six open T-slots, two on each 40mm face and one on each 20mm face. The profile is smooth, which makes it resistant to dirt and debris buildup while also being easy to clean. The 20-2040 profile is compatible with 20 series fasteners. It is a part of the smallest profile series 80/20 offers, lending itself to work spaces, machine guards, displays and panel mount racks.

Part No: 20-2020

20mm X 20mm T-Slotted Profile – Four Open T-Slots

20-2020 is a 20mm x 20mm metric 20 series square T-slot profile with four open T-slots, one on each 20mm face. The profile is smooth, which makes it resistant to dirt and debris buildup while also being easy to clean. The 20-2020 profile is compatible with all 20 series fasteners. The 20-2020 profile is part of the smallest profile series 80/20 offers and lends itself to machine guards, work benches, panel mount racks or displays. The four open T-slots enable access from any direction and are useful for mounting accessories.

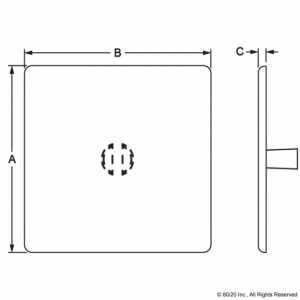

Part No: 12305

20 Series End Cap with Molded Push-In Stem

The end cap with molded push-in stem adds a finishing touch to your project and closes off profile ends to limit dust and debris buildup. It comes in black with molded push-in stems for easy installation.

Part No: 12306

20 Series End Cap with Molded Push-In Stem

The end cap with molded push-in stem adds a finishing touch to your project and closes off profile ends to limit dust and debris buildup. It comes in black with molded push-in stems for easy installation.

Part No: 12307

20 Series End Cap with Molded Push-In Stem

The end cap with molded push-in stem adds a finishing touch to your project and closes off profile ends to limit dust and debris buildup. It comes in black with molded push-in stems for easy installation.

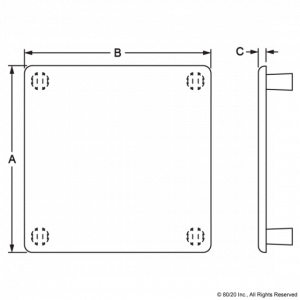

Part No: 12004

20 Series Reduction T-Slot Cover

The reduction T-slot cover slopes inward to create a flat surface and adds a finishing look while preventing dust and debris build up. It covers wires and tubes in the T-slot channel. It can also be used as panel gasket . Tip: Use a soft face mallet to tap the cover into the T-slot.

Part No: 2324

20 Series 4 Hole – Concealed Hinge

The 4 hole - concealed hinge allows you to design doors with hidden hinges when the door is closed. The hinge mounts to the inside of the frame, which makes enclosures more secure; they are not able to be dismantled when the door is shut.

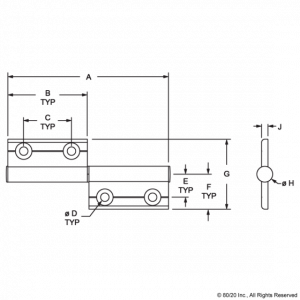

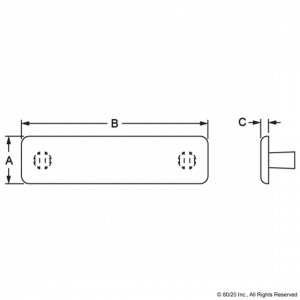

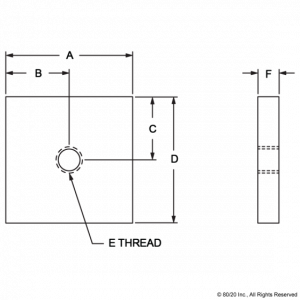

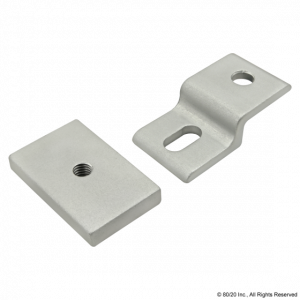

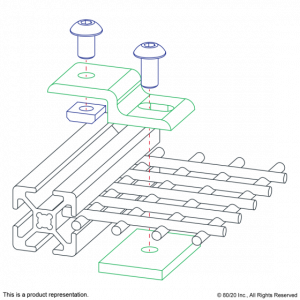

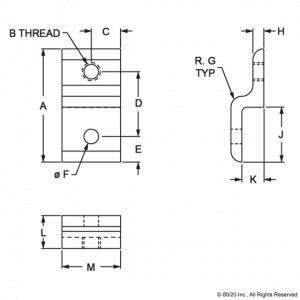

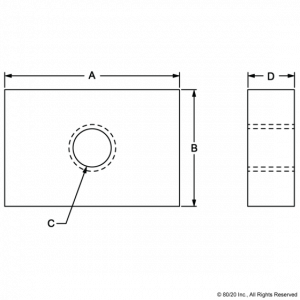

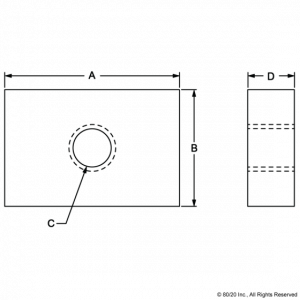

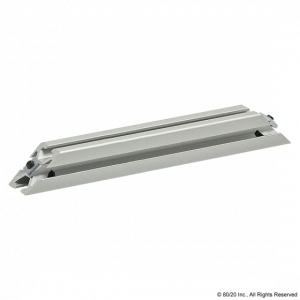

Part No: 20-2492

20 Series Narrow Backing Plate

The narrow backing plate is used with the single arm narrow mesh retainer or the double arm narrow mesh retainer to secure wire mesh or panels. The suggested hardware for the narrow backing plate should be based on the mesh or panel type and thickness.

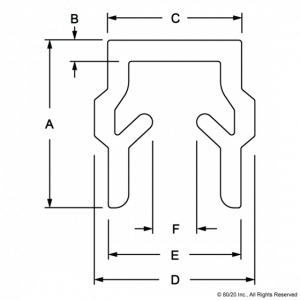

Part No: 20-2490

20 Series Single Arm Narrow Mesh Retainer

The single arm narrow mesh retainer is used to mount a mesh panel when it is recessed within the T-slot or on the profile frame. It provides stability and reduces vibration while also being a strong fastening option that is simple to use and can be easily repositioned. The single arm narrow mesh retainer is frequently used when mounting one mesh panel to a profile or in instances when larger profile series are used to mount two mesh panels. It has a slotted hole to allow for positioning so that the bolt doesn’t crash into the mesh. The mesh retainer requires a backing plate. The suggested hardware to mount the retainer to the T-slot is listed on the "Suggested Hardware" tab while the hardware for the backing plate should be based on the panel type and thickness.

Part No: 20-2491

20 Series Single Arm Narrow Mesh Retainer with Narrow Backing Plate

The single arm narrow mesh retainer with narrow backing plate consists of one single arm narrow mesh retainer and one narrow backing plate. The hardware to attach the backing plate to the retainer should be selected based on the wire mesh panel type and thickness. The suggested hardware to mount the retainer to the T-slot can be found on the "Suggested Hardware" tab.

Part No: 20-2496

20 Series Single Arm Narrow Panel Retainer

The single arm narrow panel retainer is used to mount a panel when it is recessed within the T-slot or on the profile frame. It is a strong fastening option that is simple to use, provides stability, and reduces vibration. The single arm narrow panel retainer is frequently used when mounting one panel to a profile or in instances when larger profile series are used to mount two panels. It requires a drill through machining service on the panel.

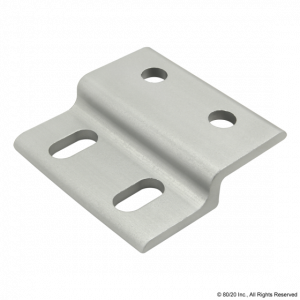

Part No: 20-2493

20 Series Single Arm Wide Mesh Retainer

The single arm wide mesh retainer is used to mount a mesh panel when it is recessed within the T-slot or on the profile frame. It provides stability and reduces vibration while also being a strong fastening option that is simple to use and easily repositioned. The single arm wide mesh retainer is frequently used when mounting one mesh panel to a profile or in instances when larger profile series are used to mount two mesh panels. It has slotted holes to allow for positioning so that the bolts don’t crash into the mesh. The mesh retainer requires a backing plate. The suggested hardware to mount the retainer to the T-slot is listed on the "Suggested Hardware" tab while the hardware for the backing plate should be based on the panel type and thickness.

Part No: 20-2494

20 Series Single Arm Wide Mesh Retainer with Wide Backing Plate

The single arm wide mesh retainer with wide backing plate consists of one single arm wide mesh retainer and one wide backing plate. The hardware to attach the backing plate to the retainer should be selected based on the wire mesh panel type and thickness. The suggested hardware to mount the retainer to the T-slot can be found on the "Suggested Hardware" tab.

Part No: 20-2497

20 Series Single Arm Wide Panel Retainer

The single arm wide panel retainer is used to mount a panel when it is recessed within the T-slot or on the profile frame. This is a stronger connection that is also simple to use, provides stability and reduces vibration. The single arm wide panel retainer is frequently used when mounting one panel to a profile or in instances when larger profile series are used to mount two panels. It requires a drill through machining service on the panel.

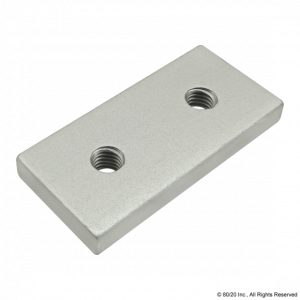

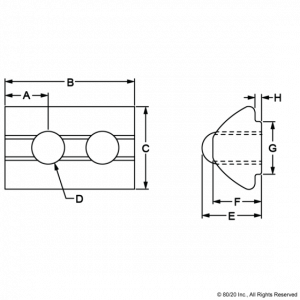

Part No: 20-2495

20 Series Wide Backing Plate

The wide backing plate is used with the single arm wide mesh retainer or the double arm wide mesh retainer to secure wire mesh or panels. The suggested hardware for the wide backing plate should be based on the mesh or panel type and thickness.

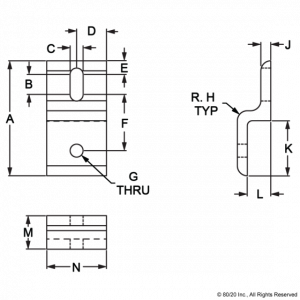

Part No: 13082

M3 Self-Aligning Roll-in T-Nut with Ball Spring

The self-aligning roll-in T-nut with ball spring is a fastening option that loads either from the profile ends or side, which is helpful for applications where the ends are inaccessible. The projection on the T-nut aligns it in the T-slot while the ball spring holds the fastener in place, even when the profile is in a vertical position. It is available with options in size, material, thread, and finish.

Part No: 13083

M4 Self-Aligning Roll-in T-Nut with Ball Spring

The self-aligning roll-in T-nut with ball spring is a fastening option that loads either from the profile ends or side, which is helpful for applications where the ends are inaccessible. The projection on the T-nut aligns it in the T-slot while the ball spring holds the fastener in place, even when the profile is in a vertical position. It is available with options in size, material, thread, and finish.

Part No: 13084

M5 Self-Aligning Roll-in T-Nut with Ball Spring

The self-aligning roll-in T-nut with ball spring is a fastening option that loads either from the profile ends or side, which is helpful for applications where the ends are inaccessible. The projection on the T-nut aligns it in the T-slot while the ball spring holds the fastener in place, even when the profile is in a vertical position. It is available with options in size, material, thread, and finish.

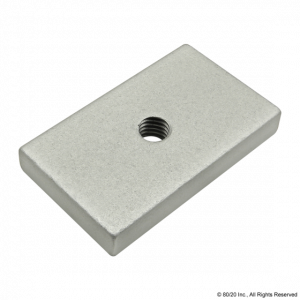

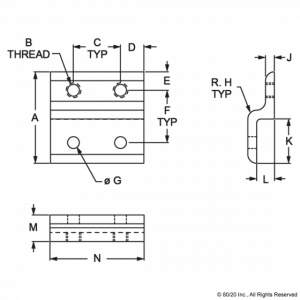

Part No: 14159

M4 Slide-in Economy T-Nut Block

The slide-in economy T-nut block is a fastening option that loads from the profile ends. It is the most cost-effective slide-in T-nut and also provides infinite positioning along the profile T-slot. This fastener is available in a variety of sizes and threads.

Part No: 14122

M5 Slide-in Economy T-Nut Block

The slide-in economy T-nut block is a fastening option that loads from the profile ends. It is the most cost-effective slide-in T-nut and also provides infinite positioning along the profile T-slot. This fastener is available in a variety of sizes and threads.

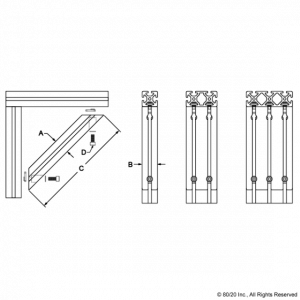

Part No: 20-2565

20-2020 45 Degree Support, 160mm Long

The 45 degree support assembly includes socket head cap screws, washers and T-nuts. The support assembly is pre-machined with counterbores and a 45 degree miter angle on both ends. This fastening method provides a clean, flush connection and is typically used to reinforce a 90 degree connection. This connection lends itself to applications with heavy loads to minimize beam deflection.

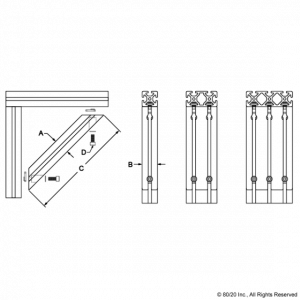

Part No: 20-2570

20-2020 45 Degree Support, 320mm Long

The 45 degree support assembly includes socket head cap screws, washers and T-nuts. The support assembly is pre-machined with counterbores and a 45 degree miter angle on both ends. This fastening method provides a clean, flush connection and is typically used to reinforce a 90 degree connection. This connection lends itself to applications with heavy loads to minimize beam deflection.